LENGTH & MATERIALS

Length of scissors

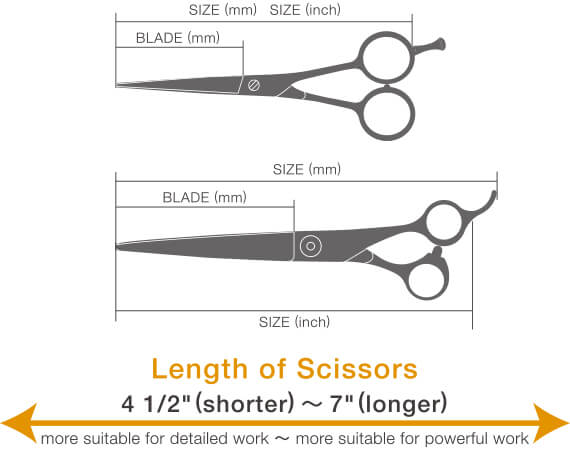

The size of scissors is usually indicated in inches.

The short ones are 4.5 inches, and long ones are up to about 8 inches. Size is selected depending on the cut techniques. Shorter scissors are more suitable for detailed work, and longer scissors are more suitable for powerful work. Cutting accurately in a straight line is the basic of the blunt cut and, therefore, the 5-inch size is the mainstream. In Asia, where the longer size is more popular, tends to be appreciated due to the greater power and different hair characteristics. The characteristics of long scissors enable efficient work because more hair can be cut at one time, and a higher flexibility can be achieved depending on the method of use.

Material for the blade

-

Cobalt Base Alloy CBA-1

Based on the scarce metal cobalt, it includes chrome, tungsten, and carbon. Cobalt base alloys do not require heat treatment as the material already has hardness, which is suitable for blades.

The other characteristics include chemical-resistance and rust-resistance. JOEWELL uses CBA1, which has higher hardness and longer life, and is suitable for dry hair, and CBA12, which has lower hardness and the characteristic of soft cutting. -

Supreme Stainless Alloy

Top quality special alloys born through the pursuit of ultra-fine composition. This material was developed from the long-term experience in manufacturing techniques and the accumulation of user comments and is suitable for hairdressing scissors. It has the best edge sharpness and durability.

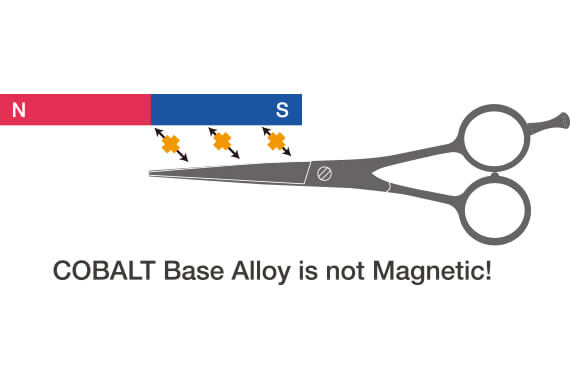

Cobalt Base Alloy

Compared to cobalt base alloys, stainless has greater hardness but cobalt has higher wear resistance. Therefore, looking at all the elements,

a cobalt base alloy has a longer life. Stainless requires heat treatment (quenching) but cobalt does not. Cobalt is not magnetic; therefore,

you can determine whether it is a cobalt base alloy or stainless (stainless including cobalt) by placing a magnet over the blade. Some products claiming to be cobalt are actually stainless.

By placing a magnet over the blade, the material can be distinguished from a cobalt base alloy or stainless.

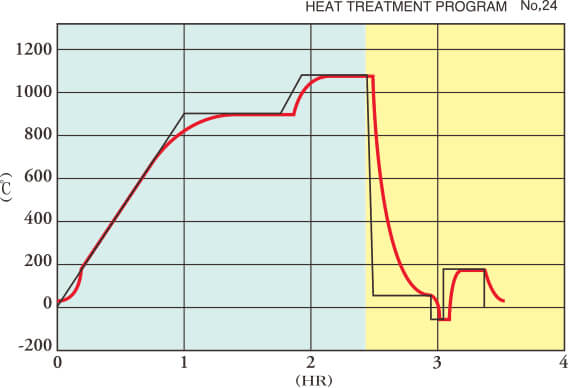

Latest Heat Treatment Techniques

Heat treatment is applied to stainless blade materials except for cobalt base alloys. A computer-controlled, full automatic vacuum heat treatment method is adopted. It can maximize the quality of the material and achieve consistent heat treatment. JOEWELL manufactures its products at the highest level of hardness that is practically possible, and the hardness is 15% higher than the general hardness of competitors’ products. It produces the best edge and durability.

Material for the handle

JOEWELL is also concerned about the handle material. We use nickel-less (0.1% or less) stainless in most of our products to ensure against metal (nickel) allergies. The countermeasure against nickel allergies is specially demanded in Europe so all of JOEWELL products in Europe are nickel allergy resistant. Also, because of the hard material used, the handle is difficult to be deformed (scissors do not easily go out of tune), and its face is difficult to get scratched. Please inquire separately for details of each product.